ABOUT CNMOULDING COMPANY

The CNMOULDING company has its own custom plastic injection mold manufacturing factory in Shanghai China. We can provide high-quality injection molds at competitive prices for global companies.

FACILITY

We are a fully equipped injection mold factory. We have complete in-house mold making capacity and proceed from mold design to CNC, EDM, wire cut, polish, mold fitting, and mold testing. Our equipment includes but is not limited to 6 sets of CNC, precision 0.005mm. 14 sets of mirror EDM, 8 sets of slow wire cut. 12 sets of injection molding machines range from 60 Ton to 800 Ton, 1 set of 2D projection measurement, and 1 set of CMM. We can build plastic injection mold and Die-casting a maximum of 7.5 tons, and molded plastic parts a Maximum of 1200g.

PEOPLE

Currently, we have 60 experienced injection mold makers employed. These mold makers are the best mold technicians in the mold-making industry. They take pride in their job. We believe people are the key to business success. A professional and stable team is the found· action of high-quality work, promises the customer’s satisfaction.

MANAGEMENT AND SERVICES

The injection mold maker project is managed by the sales rep, project manager, and quality manager. We have very professional injection mold engineers with good language skills to work closely with their help. The best mold making solutions will be provided to your companies. The latest process of your project will be accessible easily.

LOGISTIC

We have mature cooperation relationships with some of the best international logistic carriers in China. We provide customers with many options for the delivery term in a timely and safe manner.

Customer Feedback: Why am I seeking Injection Mold Factories in China?

I have been contacted by quite a few plastic injection molds making factories in China. But out of maybe 4 or 5 that sort of stands out. I am not going to make a decision until I travel to Shenzhen and visit the old factories. All I can tell you is that laws of physics do apply all over the planet, and there is a limit to precision no matter where the plastic parts are molded.

My experience has not been very positive in dealing with American mold making companies. They seem to have problems quoting because they think I will shop for them. At this point that is not the aim. I am trying to find factories capable of doing the job first. But giving you the job is not going to be automatic because you are an American company. So far I had better exchanges with Chinese injection mold manufacturers. They seem to try to be friendly and welcoming to make a tour in the factory, seem to be really interested in working with me. I have been to China several times. And I don’t mind working with them as long as ground rules are established. I am well aware of the concept of “target price” at which you will get the price but not the quality you are seeking.

CNMOULDING company

INJECTION MOLD QUALITY CONTROL

We are an ISO9001:2015 certified company in Shanghai, China. From materials incoming to finished product outgoing. We have a fully implemented quality control process to ensure a lower re-work rate, lower wastage, higher efficiency, and short delivery term. From the first article inspection to process capabilities study (PPAP). We guarantee production is stable and correct. All mold steel/resin we used strictly following customers’ quality requirements. Genuine steel purchased certificates and property specifications of plastic raw materials are always available if the customer made a clear request.

Mold quality is the foundation of our success. 90% of our new injection molds only take 1 time or 2 times of testing. Before we put them into mass production or send them to overseas customers. From materials incoming to finished workpiece before mold assembly. We have a fully implemented quality control process to ensure a lower re-work rate, lower wastage, high efficiency, and short delivery term. From the first article inspection to process capabilities study (PPAP). We guarantee production is stable and correct. All mold steel/resin we used strictly following customers’ quality requirements, steel purchased certificates and property specifications of plastic raw materials are always available.

Our quality department processed 1 set of CMM. and 1 set of 2D projects. And other measurement types of equipment. 4 experienced quality staff hired. We provide steel measurement inspection, first article inspection, and full measurement reports.

We are a good reputation company in plastic injection mold manufacturing and injection molding industries in Shanghai China, found in 2000. The molds we make are used for auto parts, household appliances, electronics, medicals, etc.

OUR SERVICES INCLUDE:

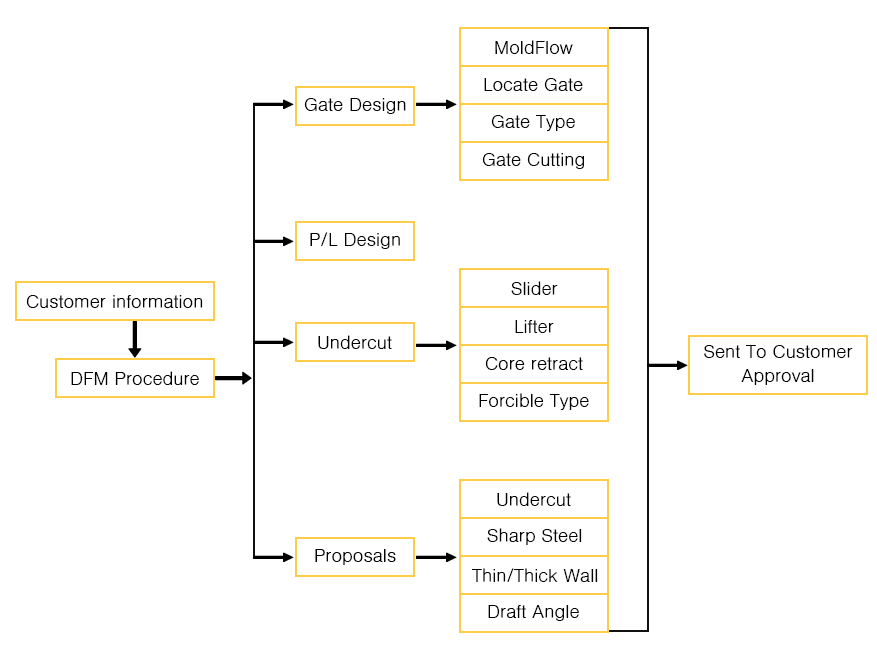

1, CAD design/mold flow analysis/DFM.

2, Custom injection mold making.

3, Plastic injection molding.

4, Prototyping, low volume injection molding.

5, Painting and assembling.

WHY CHOOSE CNMOULDING COMPANY?

Were you able to find a good source for plastic injection molds? You may find out there are very few Chinese manufacturers that could satisfy your company’s needs. We are a Chinese company with our own tooling factory in Shanghai China. Our company builds very precise and high-quality plastic injection molds exclusively for demanding the US, Canada, UK, Germany, Italy, and more companies. And we have excellent equipment including mirror EDM, etc. Our mold engineers are good at English and mold technologies. So our company is easy to communicate with. Feel free to let us know if you are finding a plastic injection mold maker in China.

BETTER CHINESE PRICES

CNMOULDING company has a unique hybrid solution for dealing with American companies. But getting better Chinese prices. Our company will be glad to review your specifications and share them with our plastic injection mold makers as well for their input. We work on a cost-plus basis. we will give a very honest quotation to build what exactly you are expecting. And have a reputation for making only top-quality molds and we stand behind our work. We think you will really like working with our company. We are also glad to give you the references of our many US customers that can tell you the kind of services we can offer.

Although sourcing plastic injection mold to Chinese companies directly can be risky and difficult to manage without experience. There are many variables. Sourcing through our company will be able to reduce your cost of tooling up to 50% compared to the USA. And lower the risk of other Chinese injection mold making companies. Our mold engineers are good at English and mold technologies. So our company is easy to communicate with. Another advantage to consider using our company. As a source is we accept full responsibility for all tooling and production and provide above-average terms.

THE CNMOULDING COMPANY-CHINA INJECTION MOLD MAKER

CNMOULDING has helped our clients to work their innovation ideas out with our full experience in injection mold and plastic injection molding. The most important difference between the price of the USA and China. China’s price is much lower than the USA’s price. That is why Apple Inc assembles its iPhone series in China.

Anyway, your choice should be based on the requirement of your product and your company’s budget. The right price is from the right manufacturer. Sending your drawings or pictures to us? Then we can evaluate your project and give you our professional suggestions.

Bear in mind: If you want all your work finished in one factory. You need to take care to visit and review the company before you make the decision. Most companies in China only do business with mold tooling. And part making separately. And they usually do not have an assembly line. If you want to put your projects in China.

Our suggestion is that you should pay attention to the medium and big-sized companies with mold tooling, and injection molding workshops. Also, an assembly line with painting, and printing. Contact us to save your time if you want to put your business in China. We always put our customer’s satisfaction in the top position.

No related posts.