Low Volume Injection Molding production company in China

Low Volume Injection Molding production company

When you design a new product, you want to try them in the market before you invest lots of money to make a big production. Now the problem comes out, the big factory or famous company has a big amount for MOQ. But you worry about the quality of a small shop. Now injection mold companies focus on providing this service of Low Volume injection molding after optimizing our management system and marketing.

Nowadays, it is important for a company to get new models into the market quickly. In most of the cases, it could be just a market-testing product with 10,000 units’ volume or even less. But the plastic parts still need to be customized by plastic injection mold to achieve the specified tolerance, finish, function. Traditionally, a hardened steel mold would require a big amount of investment before you get a simple piece. And it usually takes 8-12 weeks to finish the mold, it will lose precious time to occupy the market.

low volume company costs

Most important is the cost, Low volume mold will be much cheaper than harden up mold. Spending the same money, you can launch more projects. It will help your plastic molding company enhance the chance to succeed. if one project failed, you still have money to develop the next project.

Machining process

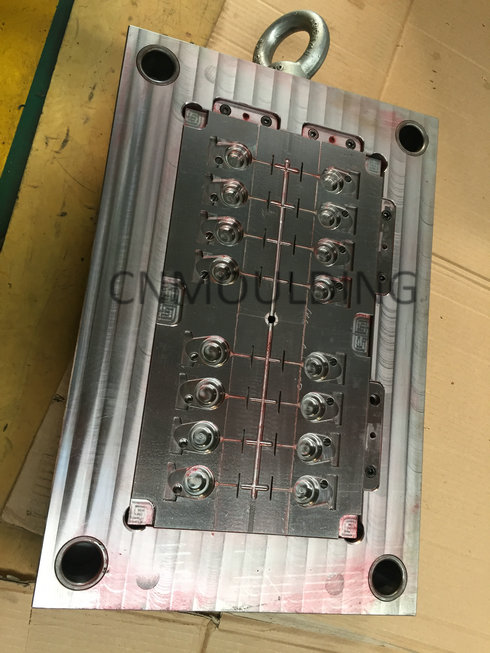

Low volume injection molding requires a mold first, start with mold design, and then CNC, EDM, wire cut, polish, etc. All processing used by making a hardened steel mold is adapted to make a mold for low volume production. Low volume mold sometimes refers to rapid tooling or prototype tooling. To achieve cost advantage, the mold uses lower grade steel(mostly local steel) or aluminum. Which don’t have to withstand hundreds of thousands of times of injection press as production mold?

Molds made by pre-hardened steel or injection molding plastics aluminum are capable of 10,000 to 300,000 molding cycles. This is enough for the needs of most projects which didn’t make a big success in the market. The lead time of building mold is shortened massively because the steel doesn’t have to be hardened up after rough CNC machining. The workability of soft steel is also better than hardened steel, which makes the processing is easier and faster. But the finish and quality is the same level as harden up steel mold

The advantage of low volume mold

- Save lots of money but never compromise with quality

- Short lead-time

- Easy to modify the tooling

- Reduce the risk of a new project