The concept of plastic injection molding

Plastic Injection molding is used to produce many things such as wire spools, package and bowl, bottle caps, automotive parts, toys, optics, some musical instruments (and parts of them), prototype china one-piece chairs and small tables, storage containers, mechanical parts (including gears). And most other plastic products available today. Injection molding is the most common modern method of manufacturing parts. It is ideal for producing high volumes of the same object.

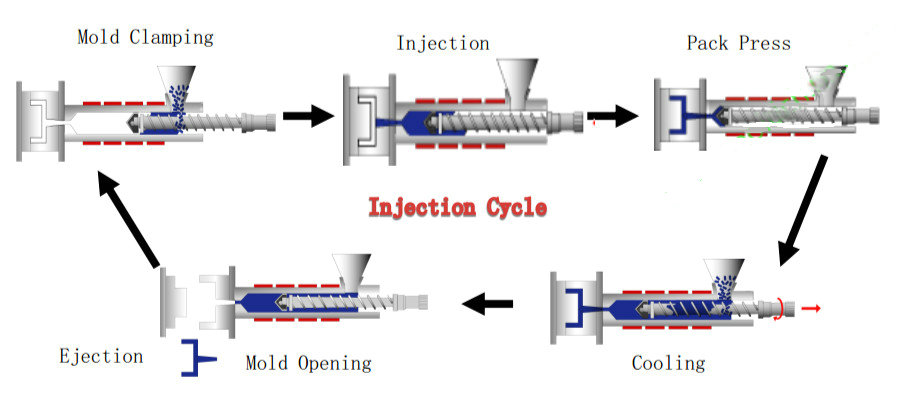

The injection molding process mainly includes 6 stages, such as closing die – filling – pressure-retaining – cooling – mold opening – demoulding. These six stages directly determine the quality of the product, and these six stages are a complete continuous process. This chapter focuses on the four stages of filling, pressure retaining, cooling, and demolding. Injection molding uses a ram or screw-type plunger to force molten plastic material into a mold cavity; this solidifies into a shape that has conformed to the contour of the mold.

Plastic injection molding

Our injection shop:

CNMOULDING is one of the famous plastic injection molding companies in China. Injection molding companies Our injection molding shop equipped 20 sets of high precision injection molding machines, range from 50ton to 650 tons. They are most import from Taiwan or Japan, our injection shop run 24 hours a day, 7 days a week automatically production services.

We are experienced with the various plastic products for automotive, medication, lighting, sports equipment, home appliance, and agriculture. Credited an ISO9001-2008 certificate since 2004. Also, have 5 IPQC people watch the production and check the quality within 24 hours. It makes sure our production keeps a stable quality. In the past 15 years. Our company already win a good reputation with stable quality and plastic molding companies reasonable prices. keep a good business relationship with 50 customers, especially from the USA and Europe.