plastic injection molding gate

Injection Molding Gate type

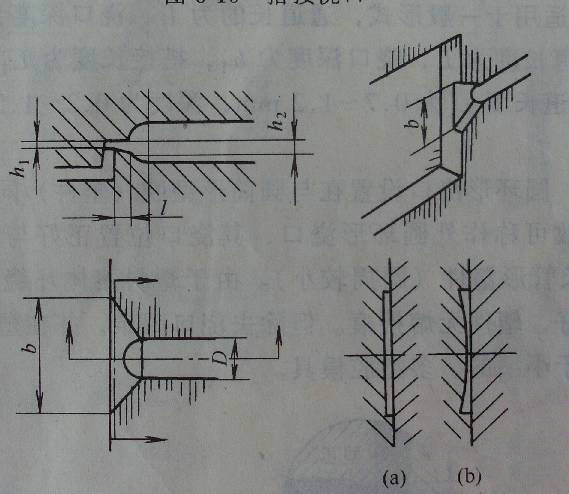

Injection Molding Film gate is well known as the flash gate (flash gate) in China. a thin film gate like a circular runner, but used in flat edges of plastic parts. it has a flat rate, the gate width can jump the whole or part of the cavity edge. The film gate is suitable for pressing Liceu pieces and is often used in large, flat plastic parts to keep the minimum of the warp. The film gate size is small, the thickness is about 0.25 ~ 0.63 mm, width is about 0.63 mm. Automatic removal of gate and mold actions, during ejection plastic parts, cut gate.

They are applied to: y avoid removing gate secondary processing. Y to maintain uniformity of cycle time, Y minimize gate marks. Automatic removal of the gate includes the following types: needle gate, the latent type gate and hot runner gate, and the valve gate.

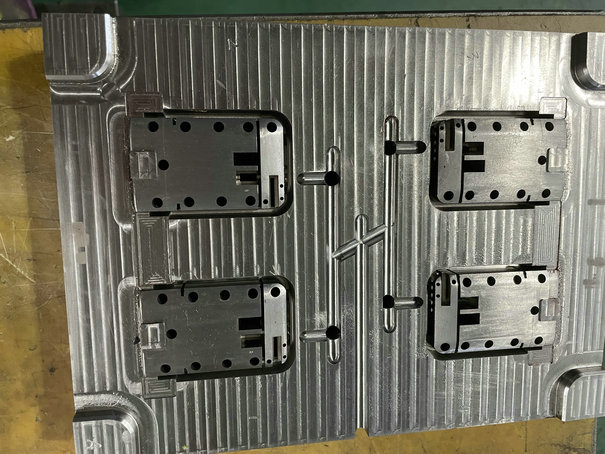

Mould gate design

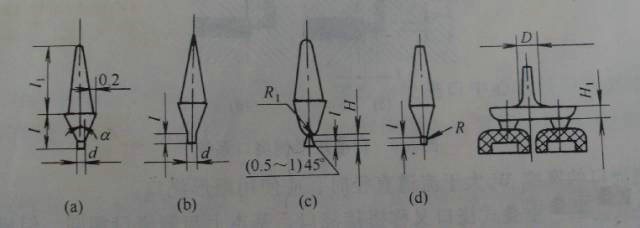

Injection molding needle gate

Pin gate

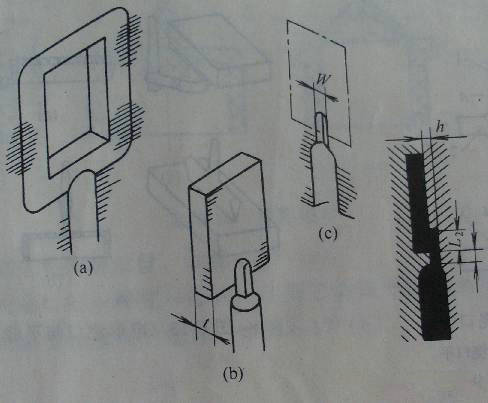

Pin gate (pin gate) is usually applied to three board mould, the runner system located in a component model online templates, cavity plastic parts meet the main parting line. The gate with a back taper Angle direction parallels the template through the middle template. When the open cavity of the main parting line, the small diameter end of the needle gate from plastics torn off, then open the port can be a parting line out port waste. This system can also open a port parting line first, then use assistive devices off the port waste. Needle gate is used most often in a single plastic part more into the water to ensure symmetrical filling or shorten the length of the flow channel to ensure the parts of the holding operation. The typical needle gate is 0.25 ~ 1.6 mm in diameter.

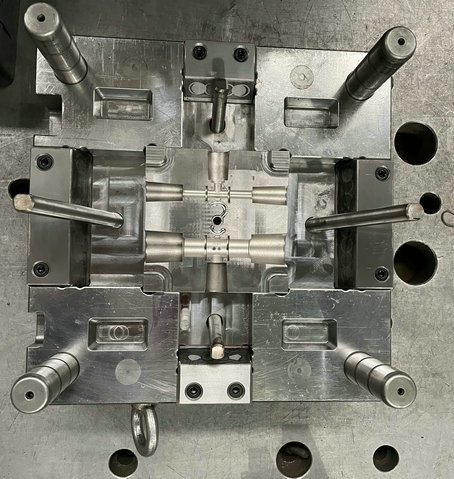

Submarine gate

Submarine gate

The latent type gate (submarine gate) or is called the tunnel gate, chisel gate, used in the two plate mold, below the parting line, the end of the passage between the cavity and processing a tilt the cone of the tunnel. Ejection parts and runner, the gate will be separated from the plastic parts. The typical latent type gate is 0.25 ~ 2.0 mm in diameter, a runner from coarse to fine until becoming a globular endpoint. If parts of the functional area have the characteristics of a large diameter of the needle, they can be connected to the latent type gate, to reduce processing costs. If the needle features occur in the hidden surface, it also cannot remove him. To multiple submerged in a cylinder inside the gate design, can replace the disk gate, and have the function that automatically removes the gate, to the periphery of the molded parts roundness than disk gate parts of roundness is poor, but also can accept it.

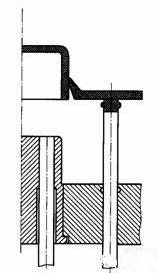

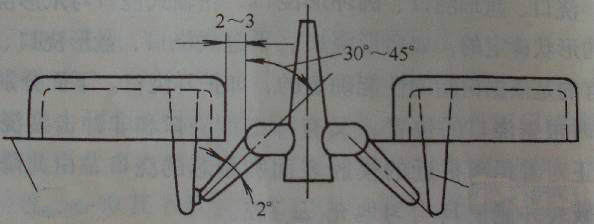

The hot runner gate

The hot runner gate is called a thermal probe gate (hot – the probe gate). usually from electrothermal vertical sprue and heat flow transmitted directly melt into the cavity, to produce plastic parts without a runner. Control the pressure maintaining cycle in plastic parts near the gate of solidification. When the template is opened, a fairly high-temperature plastic tear from the cavity.

Hot runner mold gate usually has the following 4 forms, select the appropriate gate according to the customer’s product needs.

Valve gate:

Valve gate design in the china injection molding process. In the hot runner gate, increase a needle bar to close the gate before gate solidification. It can be applied in the larger gate without a gate trace. Because the holding period is controlled by the needle bar, the valve type gate can get better the holding period and the stable quality of plastic parts.

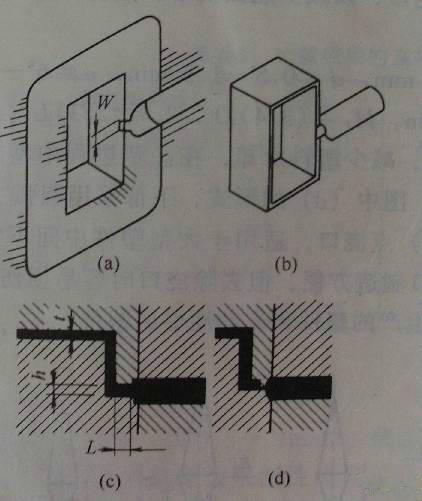

Side gate:

Side gate

The side gate automatic gate design in the injection molded parts design. The side of the gate in the general design is not automatically taken off a gate. If the product and the runner are designed at different times out, it can realize the automatic gate effect.

Bottom gate:

Bottom gate

Take the bottom gate Take the bottom side gate of the gate of improvement, products suitable for a particular shape.

1), In the case of the side gate is not permitted.

2) Avoid the fluxion phenomenon; Backoff delay needle.

3) In addition to the hard PVC, suitable for most of the products.

Fan gate:

Fan gate

The fan gate is the improved side gate, its width increases with the decrease of depth.

1), Suitable for large flat type shape products

2), The plastic into the cavity is flat, reduces the production flow, and clamps water lines.

3), Suitable for any except hard PVC plastic.

Mold gate in China

Gate of Injection Molding – we are a high-quality mold manufacturer and plastic injection molded supplier in Shanghai, China with a lower price quick turnaround.