Plastic products widely used in new energy vehicles

new energy vehicles plastic part

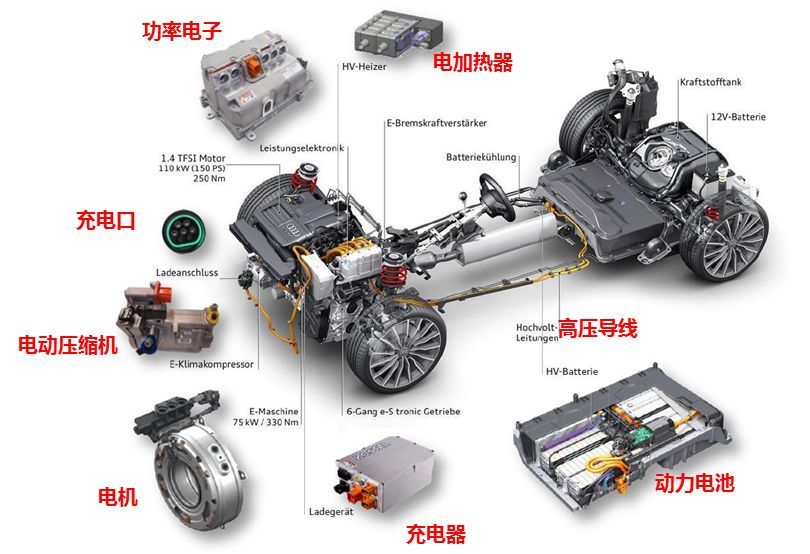

New energy vehicles (NEVs) are becoming increasingly popular and are being used to reduce carbon emissions and improve the environment. Plastic products are widely used in the manufacturing of NEVs due to their lightweight, high strength, and durability. Here are some examples of plastic products used in NEVs:

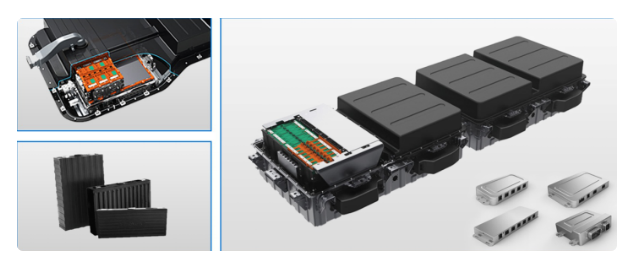

Battery casings:

The casings of electric vehicle batteries are often made of plastic due to their lightweight and high strength.

Interior components:

Plastic is commonly used in the interior of NEVs for components such as dashboards, door panels, and seats. These components are often made from recycled plastic to further reduce the environmental impact of the vehicle.

Exterior components:

Plastic is also used in the exterior of NEVs for components such as bumpers, fenders, and grilles. These components are lightweight and durable, which helps to improve the vehicle’s overall efficiency.

Charging stations:

Plastic is used in the construction of charging stations for NEVs, as it is lightweight, durable, and weather-resistant.

Overall, plastic products are an important part of the manufacturing process for NEVs and help to reduce the environmental impact of these vehicles.

Plastic products will help reduce car weight

new energy vehicles plastic part

Compared with traditional alloy materials, plastic parts have unparalleled advantages. Plastic products will help reduce the weight of cars. Data shows that for every 10% reduction in vehicle weight, fuel economy can increase by 5%. So new energy vehicles using plastic products can run farther.

Plastic products can also reduce the production cost of car companies.

A simple injection-molded plastic part can perform the function of welding many metal parts together. The plastic can be molded into a more complex shape than the steel assembly. Which can reduce the integration process The number of parts used.

In addition, the elastic deformation characteristics of plastic products absorb a large amount of collision energy. Have a greater buffering effect on strong impacts, and play a good role in protecting vehicles and passengers. Plastics have strong corrosion resistance and will not be corroded if they are damaged locally. However, once the paint surface is damaged or the anti-corrosion is not well done in advance. It is easy to rust and corrodes. This not only affects the appearance of the car body. But also poses a safety hazard.

Can modify plastics

According to the composition of the plastic. Plastics with the required properties can be prepared by adding different fillers.

, and hardeners, and mechanical strength and processing. And forming properties of the plastic can be modified to meet the requirements of different parts of the car. It can be said that plastic has contributed to the rapid development of new energy vehicles. And the rapid development of new energy vehicles has opened up a broad market for plastics.