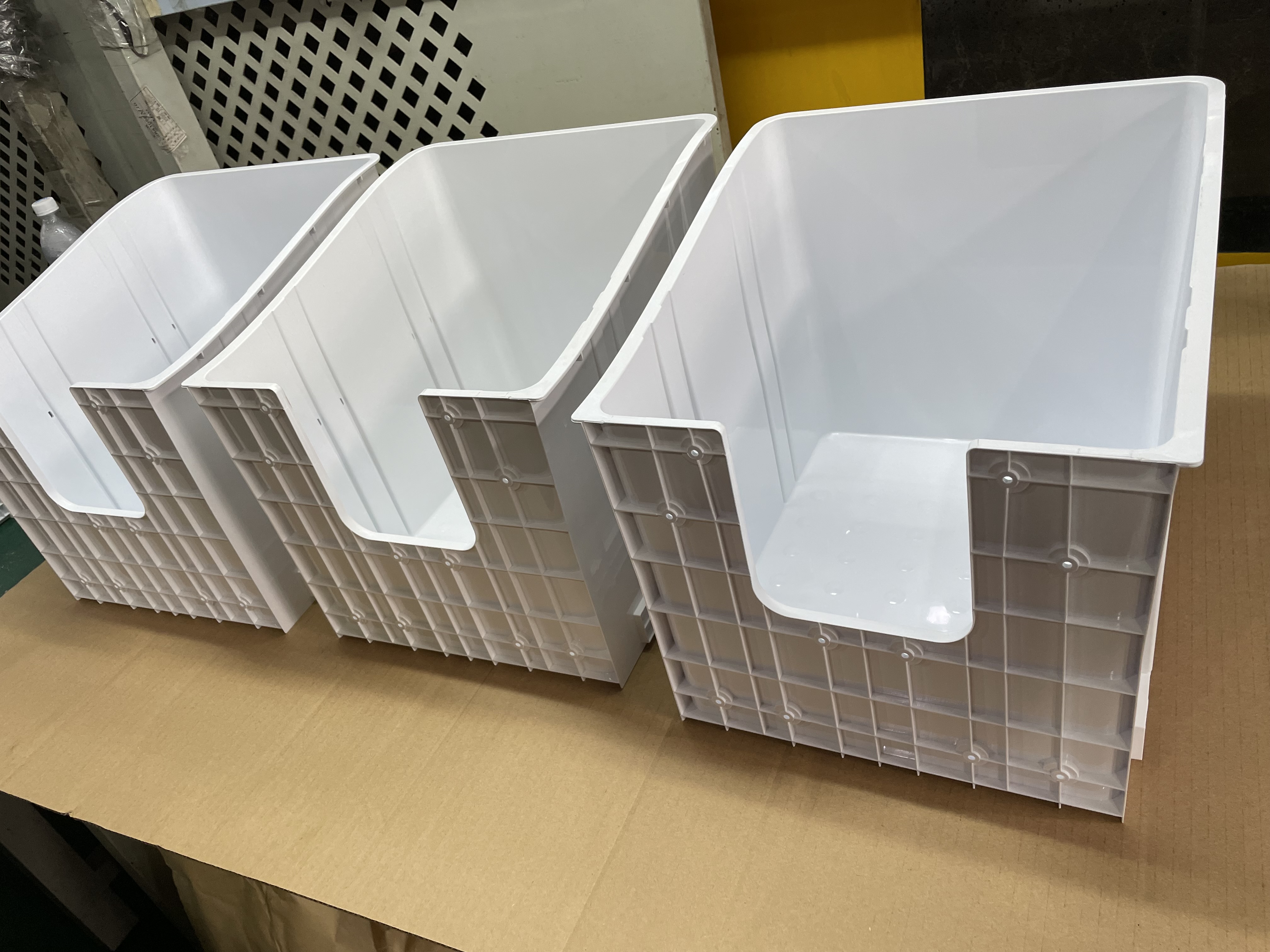

This is our newest refrigerator drawer, and what makes it special is that it’s made of food grade material -tritan copolyster.

tritan copolyster

Tritan Full name: Tritan Copolyester is a new generation copolyester developed by Eastman Corporation. Due to people’s pursuit of quality of life and health, the market’s environmental requirements for plastic raw materials are also increasing, such as PC hydrolysis will produce BPA (bisphenol-A). In recent years, studies have shown that humans (including animals), such as long-term intake of trace amounts of BPA, is very likely to have adverse effects on the reproductive system, destroy the balance of sex ratio, so some countries and regions have restricted or banned PC. Eastman has developed a new generation of tritan copolyster in the context of a market where manufacturers are under pressure to be environmentally friendly and are looking for alternatives to PC.

Tritan is environmentally safe

The Tritan is FDA certified (Food Contact Notification (FCN) No.729) to specify the material for infant and toddler products in the United States and Europe.

tritan copolyster material advantages

Easy reprocessing

Tritan can be applied to secondary processing methods including: UV glue bonding, ultrasonic welding, surface printing spray painting, surface vacuum plating, etc.

Product residual stress is small

After injection molding, the residual stress of the product is smaller than that of PC, and there is no need to do subsequent annealing treatment. Products manufactured by Tritan are more durable because there is less chance of cracking due to residual stress during use.

Excellent chemical and hydrolysis resistance

Tritan is resistant to detergents, cleaners, hydrocarbon solvents, oils, perfumes, etc. Resistant to hydrolysis in hot and humid environments.

High temperature resistance

The low pressure thermal deformation temperature (HDT@0.455MPa) is between 94℃ and 109℃ according to the brand.

Good liquidity

Under the test conditions of 2.16kgf pressure and 280℃ melt temperature, the melt finger (MI) varies from 15.3 to 29.5 according to the

brand.

BPA-free

Tritan is BPA-free during polymerization and does not release BPA during use, meeting environmental and FDA requ irements.

Clear and transparent

Transmittance >90%, fog <1%, crystal luster.

Excellent impact strength

There is no notch impact continuously, and the notched impact strength is between 650-980J/m depending on the brand, which is comparable to the impact strength of PC.

Easy molding

Tritan brands can be processed by injection, extrusion, EBM, ISBM and other methods. In general, molds that can be produced normally with PC can be produced by Tritan without modification, and the production cycle time is very close.