Your ISO-Certified Precision Injection Molding Partner in Shanghai China

As an ISO-certified manufacturer, we deliver excellence across sectors including New Energy Vehicles (NEV), electronics, medical devices, pet products, and high-precision industrial components. Whether you require rapid prototypes or high-volume mass production, our engineering expertise ensures quality every time.

End-to-End Injection Molding Solutions

from a Trusted China Manufacturer From initial concept to full-scale production, we provide a seamless manufacturing experience backed by advanced engineering and in-house tooling.

Advanced Manufacturing Capabilities:

From initial concept to full-scale production, we provide a seamless manufacturing experience backed by advanced engineering and in-house tooling.

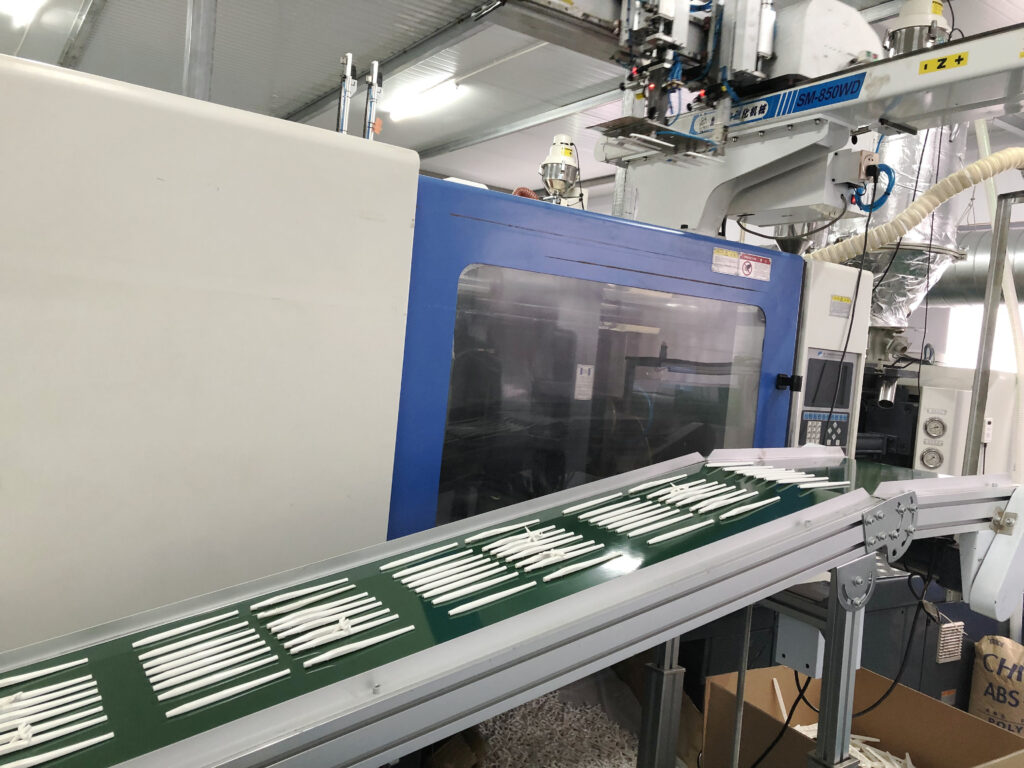

Custom Injection Molding Services: Professional production of plastic parts and components for automotive, medical, and consumer sectors.

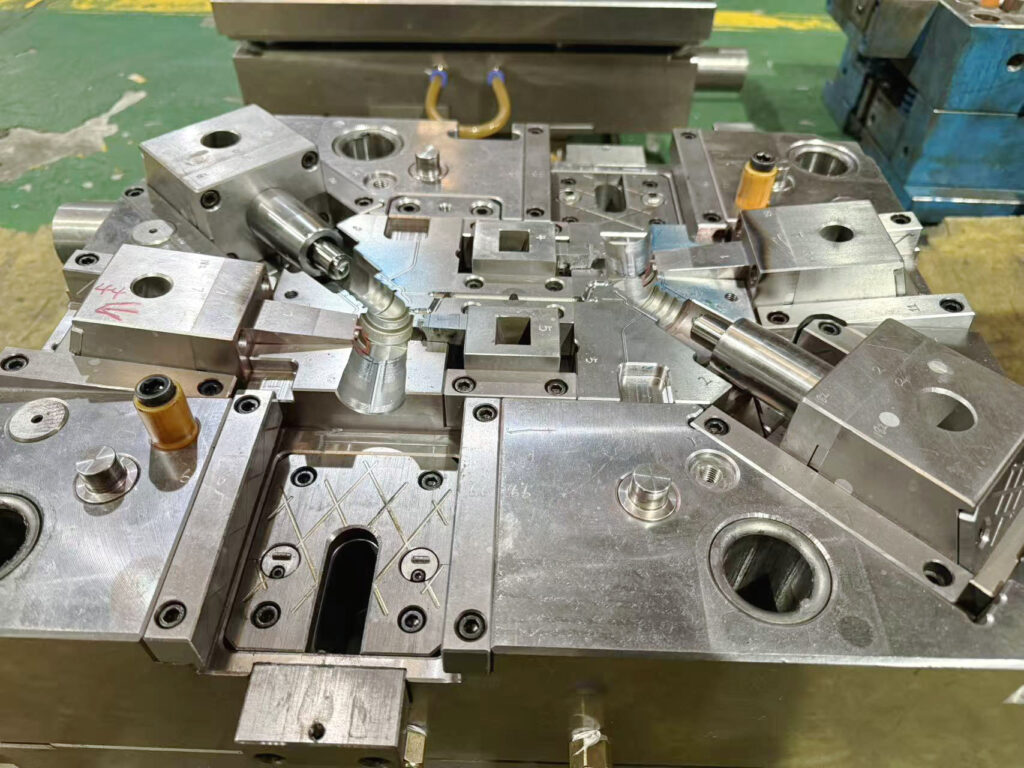

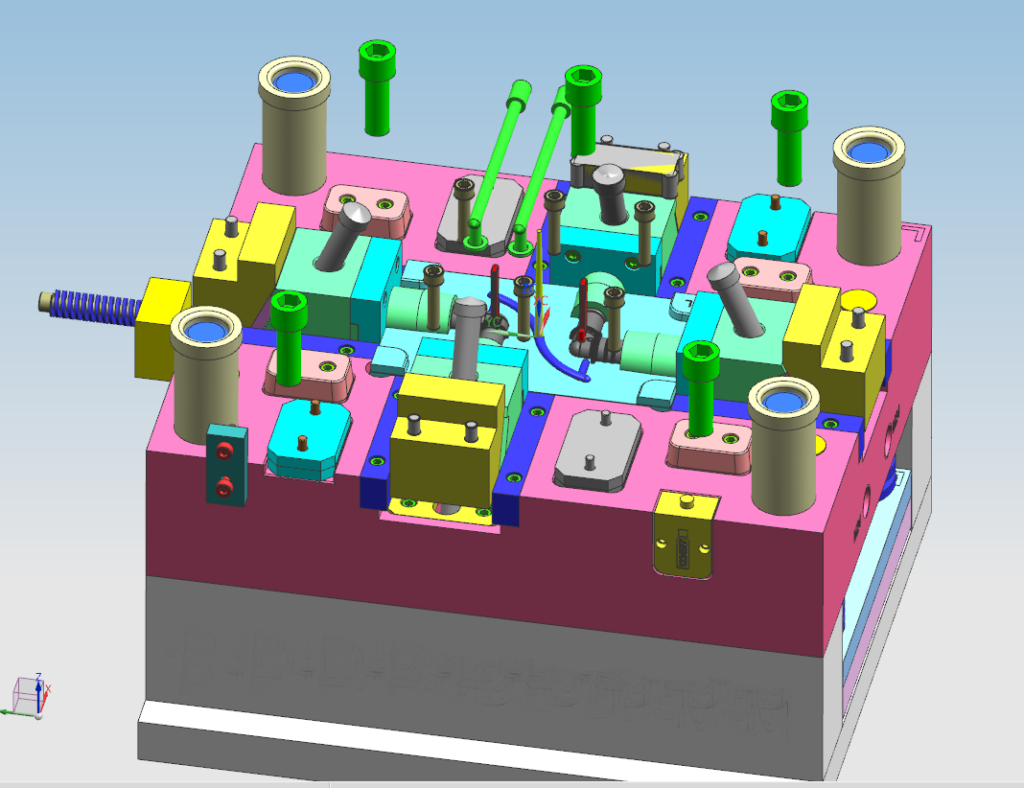

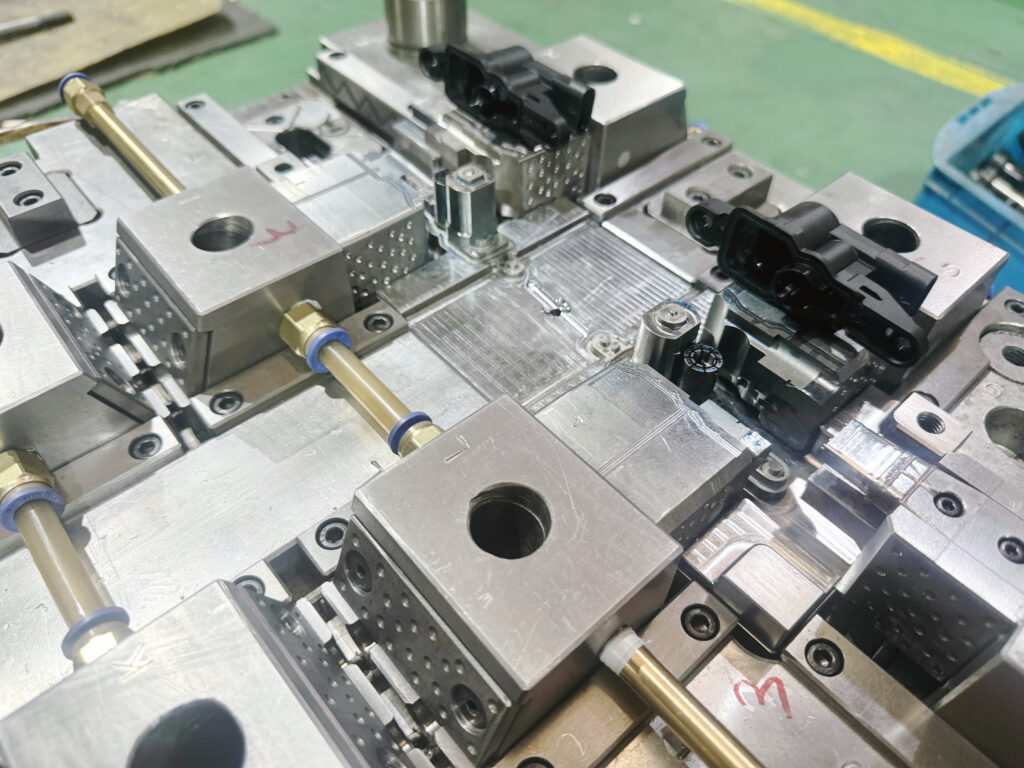

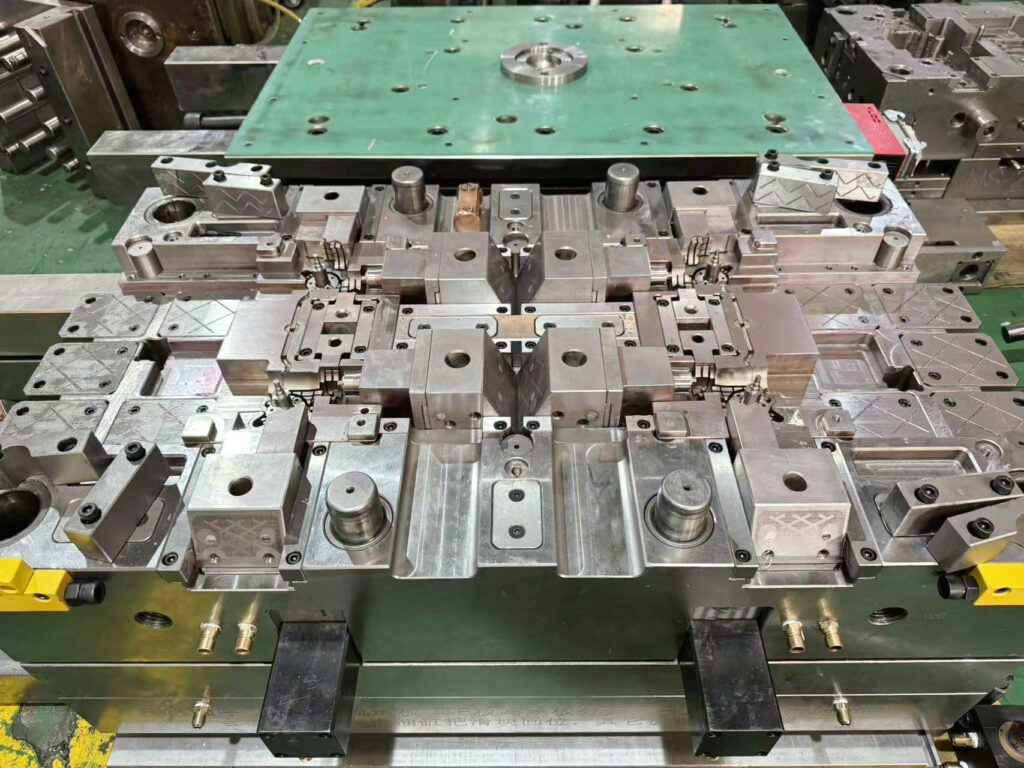

Precision Mold Design & Engineering: Our Shanghai-based engineers design high-performance molds optimized for durability and manufacturability.

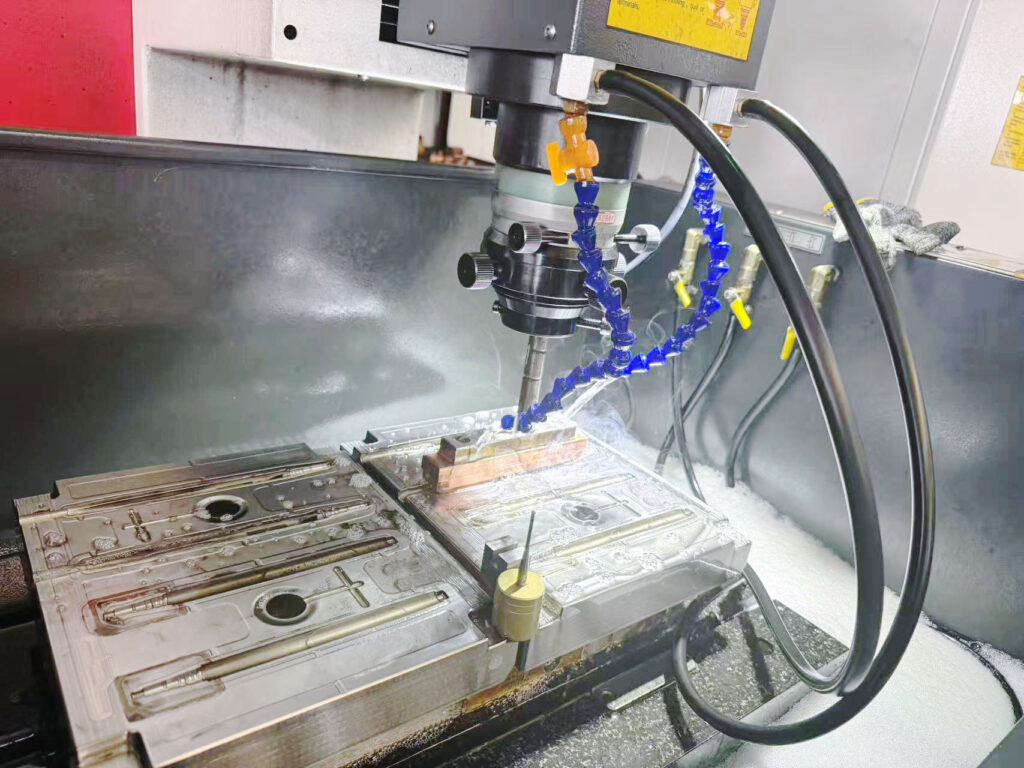

In-House China Tooling: We offer fast lead times and competitive pricing through our comprehensive in-house mold-making capabilities.

Rigorous Quality Control: Every project undergoes strict inspection to ensure consistency from the first sample to the final production run

Precision Plastic Injection Parts: High-performance components manufactured to exact specifications using a comprehensive range of engineering-grade resins.

Thin Wall & Insert Molding: Specialized, high-speed processes for lightweight designs and the integration of metal components into plastic parts.

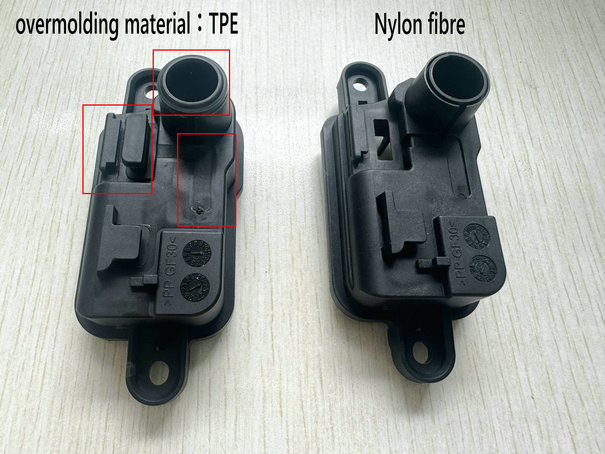

Custom Overmolding Solutions: Expert integration of multiple materials—typically a rigid plastic substrate with a soft TPE/TPU elastomer. This process enhances ergonomic grip, provides shock absorption, and creates superior environmental seals without the need for adhesives.

High-Precision Tooling: In-house mold design and fabrication, utilizing advanced CNC and EDM technology to ensure stable, long-term production and consistent part quality.

Why Choose CNMOULDING?

1. Zero-Defect Quality Engineering

The Pain: Tired of receiving parts that don’t fit or fail in the field? Our Solution: We implement a strict ISO 9001:2015 certified workflow. From DFM (Design for Manufacturing) analysis to T1 samples and final OQC, we ensure every dimension matches your 2D/3D specifications. We don’t just mold; we engineer for reliability.

2. Radical Transparency & Communication

The Pain: Communication gaps and “disappearing” suppliers after the deposit is paid. Our Solution: Our engineering team speaks fluent technical English. You get weekly progress reports with photos and videos of your mold trial. We act as your “factory on the ground” in China, ensuring no detail is lost in translation.

3. Accelerated Time-to-Market

The Pain: Market windows are closing while you wait for slow tooling cycles. Our Solution: With our in-house CNC and EDM centers, we cut lead times by 15-20%. Whether it’s a rapid prototype or a multi-cavity production mold, we optimize the cooling cycle and mold structure to get your products to market faster.

Industry-Specific Tooling Solutions: Automotive to Pet Products

We adapt our mold manufacturing process to meet the stringent regulations and performance demands of diverse sectors:

| Industry | Focus & Expertise |

| Automotive | Durable, high-precision molds for functional engine components and interior trim. |

| Medical & Healthcare | Clean-room compatible tooling and high-precision molds for critical medical devices. |

| Pet Care Products | Innovative, safe, and bite-resistant plastic components for the global pet market. |

| Electronics & Industrial | Advanced thin-wall molding and rugged components for industrial equipment. |

| Consumer Goods | High-finish molds for household products and aesthetic lifestyle brands. |

No related posts.